Saffiano leather has been an integral part of luxury boutiques around the world for some years now. The famous Italian textured leather is much talked about as one of the best leathers on the market. But does it really live up to its reputation?

To answer this question, we first need to understand what Saffiano leather is.

What is Saffiano Leather?

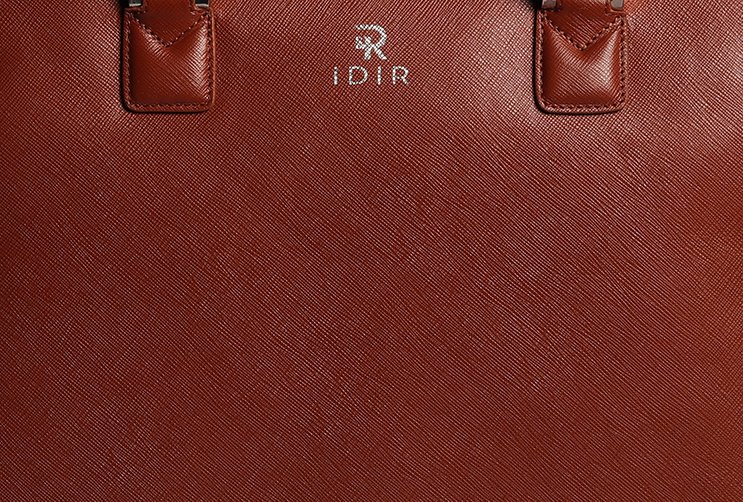

Saffiano leather is a luxurious material known for its unique texture and durability. Originating from Italy, it undergoes a distinctive crafting process, resulting in a crosshatch pattern that not only enhances its visual appeal but also contributes to its resilience.

The story of Saffiano leather

The history of crosshatch patterned leather began in 1913 in Milan, Italy, when two brothers set up a small boutique together. Mario and Martino sold luxury leather trunks, handbags and accessories.

Legend has it that Mario himself invented leather with a crosshatch pattern. Saffiano, created in 1913, sold so well that only 6 years later, in 1919, this Saffiano leather became the favorite leather of the Italian royal family. 👑

The two brothers patented the leather and have since used it on many high-end products. The patent has since expired and most fashion and/or luxury brands have a Saffiano handbag or wallet in their catalog.

What’s so special about Saffiano leather?

The finish, the ethics and the price. Don’t expect to get good Saffiano leather for cheap, because of its notoriously complex manufacturing technique.

How is Saffiano leather made?

The Saffiano leather manufacturing process is complex, with 4 stages that are familiar to the general public. These are leather preparation, heating, pressing and finishing.

- The first step is to “prepare” the leather. Saffiano is rarely dyed, but if it is, it is done during the preparation process. A translucent finish can be applied to add various properties to the leather, or it can be colored. This step is optional and will depend on the intended use of the final product.

- The leather must now be heated; this step makes the hide suppler and more compatible with the materials that will be pressed in the following steps. The temperature in the machine is 70°C (165°F) 🔥.

- The leather, now hot, is pressed against large metal plates with heavy pressure. These are pressed for 10-15 seconds to leave their shape with the cross-hatched pattern permanently in the hide.

- The final stage is the application of the finish, which is usually wax. The finish makes the leather scratch- and water-resistant, glossy and gives it the desired color.

Italian Mastery and Moroccan Expertise

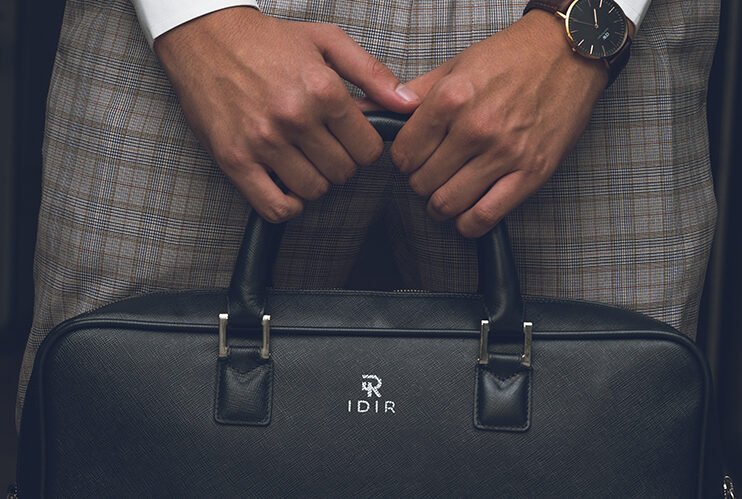

Sourced from the finest Italian tanneries, our Saffiano leather is carefully selected for its quality and authenticity. The transformative journey then continues in Morocco, where skilled artisans, with years of experience, bring this material to life. This collaboration results in ‘IDIR’ business bags that seamlessly merge the best of Italian elegance with the meticulous craftsmanship of Moroccan artisans.

The Special Appeal of Saffiano Leather

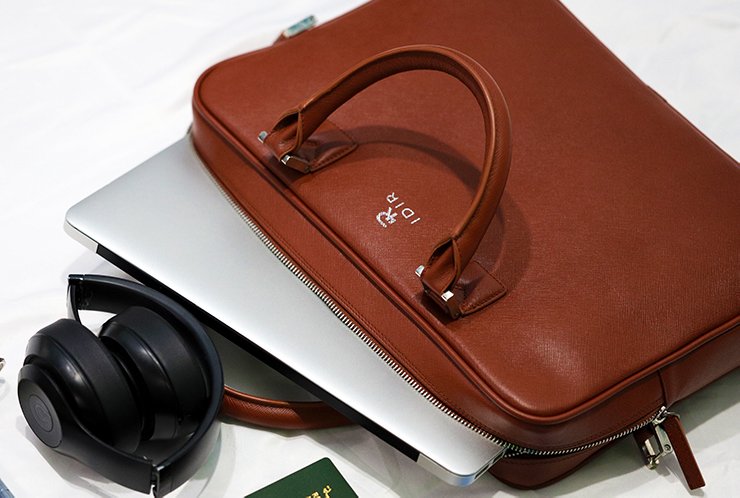

What makes Saffiano leather special is not just its refined aesthetics but also its practical benefits. The crosshatch pattern not only adds a touch of sophistication but also makes the leather highly resistant to scratches, water and sun, ensuring your ‘IDIR’ business bag maintains its pristine appearance, even with daily use, features that some leathers only dream of having.

In essence, the Saffiano leather used in ‘IDIR’ business bags represents a harmonious blend of heritage and craftsmanship. It’s not just a material; it’s a testament to the dedication we put into creating products that stand the test of time, delivering both elegance and functionality.

Experience the allure of Saffiano leather with ‘IDIR’ – where tradition meets modernity, and every detail is crafted with utmost care. Take a look at our collection and choose the best gifts for your loved ones (including yourself): https://idirbags.com/full-shop/

Don’t forget to follow us on Instagram

Leave A Comment